Cured in Place Piping

Cured-in-Place-Pipe (CIPP) lining is sewer pipe repair method that is faster and less expensive than other methods that dig trenches to replace old, damaged sewer pipes. During CIPP, crews access pipes through existing manholes.

The City of Bend maintains over 471 miles of sewer pipes throughout the city. As this infrastructure ages, it requires maintenance and rehabilitation to maintain safe, reliable transportation of sewage from the city to the Water Reclamation Facility for treatment. Pipe rehabilitation often consists of two choices: pipe replacement, or in situ pipe repair using Cured in Place Pipe liners (CIPP). CIPP lining is sewer pipe repair method that is faster and less expensive than other methods that require extensive excavation to replace old or damaged sewer pipes. With CIPP, crews access pipes through existing manholes to complete rehabilitation projects, making the process less invasive.

During CIPP project construction, crews insert a flexible felt liner inside the existing sewer pipe. The liner is inflated to press firmly against the inside wall of the old pipe. The liner is then exposed to either heat (Thermal CIPP) or ultraviolet light (UV CIPP) to “cure” or harden the pipe. This creates a rigid and smooth interior surface that seals cracks and restores the integrity of the old pipe to like-new condition. CIPP saves time and costs less than other kinds of repair by limiting traffic interruptions and requiring little or no digging. CIPP is a proven method of sewer repair and rehabilitation that has been used throughout the United States for decades.

Types of CIPP

UV CIPP

Ultraviolet light (UV) cured CIPP is a method of curing a pipe liner by exposing the resin within the pipe liner to a strong dose of ultraviolet light. This method is beneficial because the time to cure the liners is extremely short, allowing for the rehabilitation project to go much quicker. Additionally, as steam is not used in the curing process, there are less issues with odor associated with steam discharges. A constraint of UV curing is that this process can only be done on straight stretches of pipe, as the trains of UV lights used to cure cannot easily adjust to bends and slope changes.

Thermal CIPP

This is historically the most common method of curing pipe liners. This process involves using heated steam to both form a pipe liner to the host pipe, as well as to cure the resin. This method is preferred for very narrow pipes, as well as pipes that bend or are heavily eroded, as the steam can adapt to any shape. The downside of this technology is that it takes longer, as well as has the steam discharge, which can cause odor issues in the vicinity of the project.

What to Expect During Construction

If a CIPP project is scheduled to take place in your neighborhood or near your place of business, you or your business will be notified by the City of Bend Utility Department or its Contractor. The existing sewer lines will then be prepped for the CIPP process, which involves Vactor trucks cleaning the lines with high-pressured water, virtual inspection of the lines and spot repairs, which may require excavation.

Once preparation is complete, crews will set up at manholes and begin the CIPP process. You may notice steam coming out of standpipes that are set up and certain manholes, which is part of the curing process. Although most of this work will typically take place on weekdays during normal business hours, nighttime and weekend work may occur in areas that experience higher than usual traffic volumes. In most instances, the pipe lining process will be completed within a day at each location

While a CIPP project is taking place, you may experience minor traffic interruptions. For your safety and the safety of the workers, please avoid driving in construction areas. As with any construction project, stay clear of work zones and adhere to signs and safety barriers.

As with most construction, sewer rehabilitation projects may result in:

- Increased noise, dirt, dust, and/or vibrations

- Construction traffic and staging of large equipment in the area

- Lane or road closures with possible detours

- Parking restrictions in or near the work area

- Some construction projects may require temporary service disruptions

Limited Water Use

If your home or business is connected to the sewer line being rehabilitated, your sewer service will be temporarily blocked off from the sewer mainline once the liner is inflated. This will prevent any water leaving your home or business from flowing into the sewer main while the liner is curing. Once the liner has cured, a robot will be sent into the new pipe to cut a hole where your sewer service is connected, and your service will be restored.

To avoid having wastewater back up into your home or business, you may be asked to limit your water use while the lining process takes place. You should avoid taking showers or baths, running your dishwasher and washing machine, and also be sure to turn off all sump pumps connected to your sewer service. Flush your toilets only sparingly. Using small amounts of water to wash your hands or brush your teeth is okay.

Unpleasant Odors

When heat, in the form of steam, is used to cure the liner, it produces an odor that may smell similar to plastic or glue. This odor is from the chemical styrene, which is an ingredient used in the resin of the liner. The resin is the part of the liner that reacts with heat and hardens.

The odor associated with styrene can be smelled at extremely low levels, as low as concentrations of 0.14 parts per million (ppm). While this odor may be unpleasant, the amount of airborne styrene generated from the CIPP process is not a health risk. This has been verified through onsite testing and monitoring efforts of various agencies, including Oregon’s State Accident Insurance Fund (SAIF). It is also a requirement that the contractor continuously monitors styrene gas levels associated with the construction to ensure the safety of the workers and anyone near the jobsite. Once the process is complete, you can expect the odor to dissipate quickly.

How to prevent odors from entering your home or business

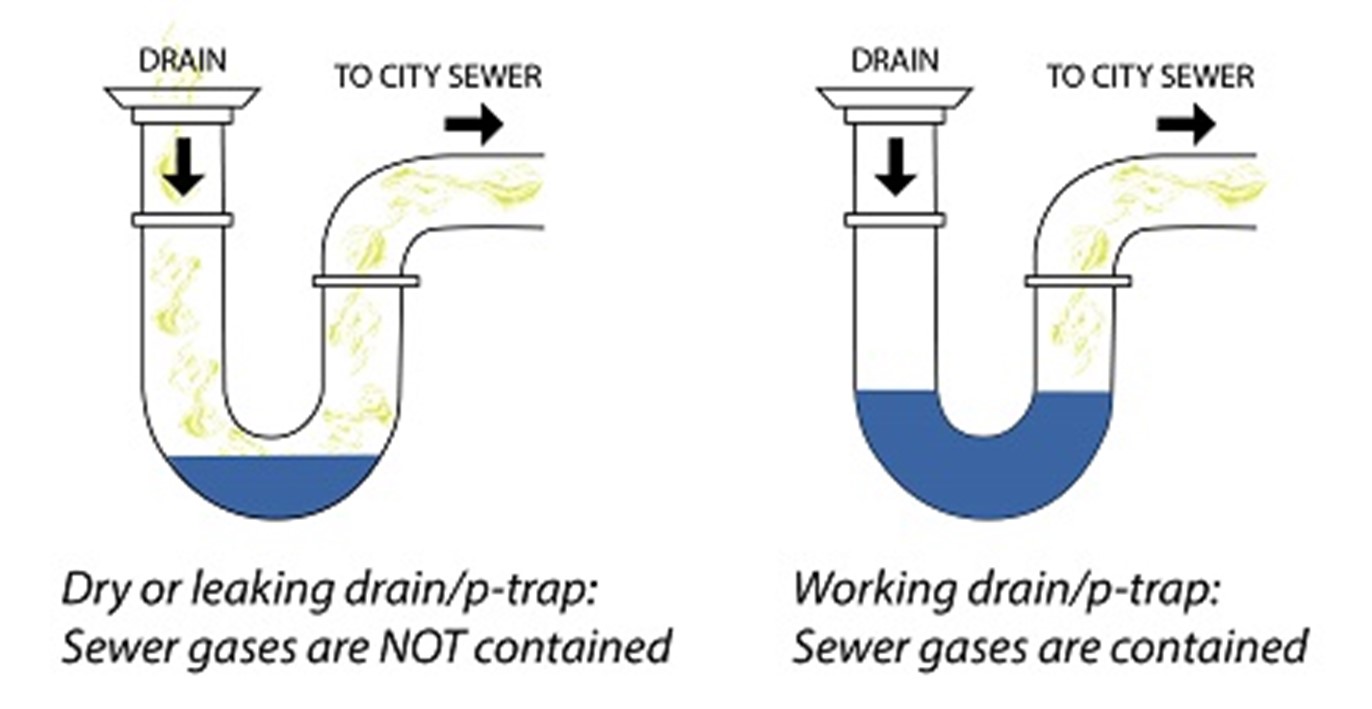

You can help prevent odors from entering your home or building by pouring water down all floor drains, sinks, and tubs to help ensure a water barrier is maintained in each drain’s P-trap.

You can help prevent odors from entering your home or building by pouring water down all floor drains, sinks, and tubs to help ensure a water barrier is maintained in each drain’s P-trap.

Further measures may be taken to help prevent the backflow of odors by temporarily taping over your drains or placing a plastic bag filled with water over them.

You may notice steam emitting from manholes while the work is taking place. This steam may produce odors in the outside environment. Keeping your windows closed and sealing off any neutral vents will help ensure outside odors do not enter your home or business. If you do experience odors in your home or building, open windows to help ventilate the area.

More Information about Styrene Odors Associated with CIPP

- 2016 Report from SAIF

- Public Health Statement from CDC

- Fact Sheet on Styrene from CDC

- PDF from Insituform or manufacturer of specific liner being used (if applicable)